Home

»

Om Selskapet

»

Tinnstøpings bearbeidelse

Tinnstøpings bearbeidelse

Teknikk til tinns bearbeidelse har veldig gamle røtter og første artikkler produsent var laget fra metallplates varmering, så kunne det være smidd med hammer i alle forskjellige fasene. Formene som bruktes var på jord, kritt og stein med disse kunne lages tinnstøping. Disse formene ble erstatt fra former I kobber, bronse, støpejern og jern. Etter støping, lagtes tinns objekter siste hånd på dreiebenk, så ble tinnstøpings detaljer sveiset på grunnformen. Tinns bearbeidelse har ikke utviklet i tid, teknikk å lage skåler, boller, fat, tallerkner, bestikk, serviser og resten i alle slag er alltid håndlaget og ses kunstnerisk ut i dag også.

Utformingen og gjennomføringen til hvert modell utføres personlig fra eierne og de ansatte. Noen bilder som viser tinns bearbeidelse:

Prototyps opprettelse: The first prototype can be made of wood, wax, directly in pewter and recently also taking advantage of the rapid prototyping of 3D printers. Got the prototype is necessary to duplicate it to get the pewter model that will serve as a matrix for the creation of the molds. The matrix is usually achieved by using the technique of sand casting as shown in the photograph on the right.

Prototyps opprettelse: The first prototype can be made of wood, wax, directly in pewter and recently also taking advantage of the rapid prototyping of 3D printers. Got the prototype is necessary to duplicate it to get the pewter model that will serve as a matrix for the creation of the molds. The matrix is usually achieved by using the technique of sand casting as shown in the photograph on the right.

Moulds: Each pewter piece is made up of a number of different moulds; one for the main body, and others for the different components. Some pieces require as many as seven different moulds. Modern moulds are made from silicon rubber, although some of the original iron moulds are still used and sometimes, for small quantities, are also used plaster molds.

Moulds: Each pewter piece is made up of a number of different moulds; one for the main body, and others for the different components. Some pieces require as many as seven different moulds. Modern moulds are made from silicon rubber, although some of the original iron moulds are still used and sometimes, for small quantities, are also used plaster molds.

Tinnstøping: The raw materials (tin, copper and antimony) are cut up and heated to 350° in a kiln, and very quickly a beautiful molten liquid is formed, which, using a casting ladle, is poured into mould with extreme care.

Once cooled, the pewter is gently extracted and any superflous lumps and bumps leftover from the casting process are removed.

Tinnstøping: The raw materials (tin, copper and antimony) are cut up and heated to 350° in a kiln, and very quickly a beautiful molten liquid is formed, which, using a casting ladle, is poured into mould with extreme care.

Once cooled, the pewter is gently extracted and any superflous lumps and bumps leftover from the casting process are removed.

fjerning av delene: At this point any decorative chiseling an engraving is undertaken, including touchmarks, to enhance the overall character of the object.

fjerning av delene: At this point any decorative chiseling an engraving is undertaken, including touchmarks, to enhance the overall character of the object.

Lodding: Each piece is then assembled, welded and soldered by hand. This is an extremely skilful and technical procedure, especially with pieces designed to hold liquids.

Lodding: Each piece is then assembled, welded and soldered by hand. This is an extremely skilful and technical procedure, especially with pieces designed to hold liquids.

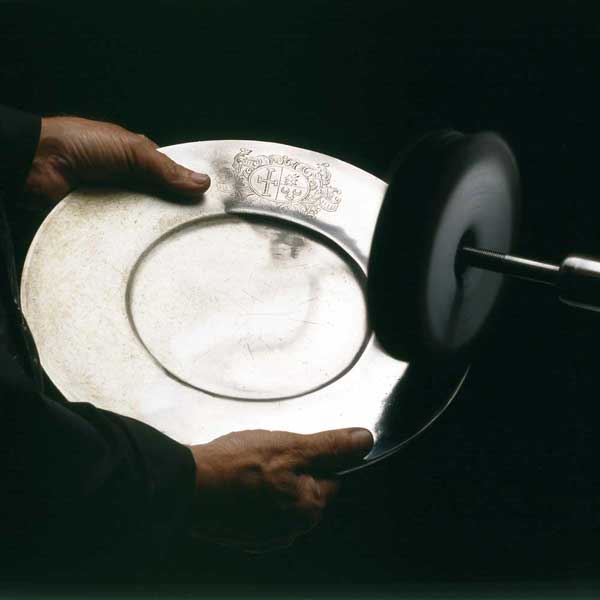

Finsliping: By skilled polishing and then rubbing using increasingly fine graded wool, 'finishing' rids the surface of any roughness and imperfections, yet retains the character of the piece. The final buff is undertaken using a fine polishing cloth.

Finsliping: By skilled polishing and then rubbing using increasingly fine graded wool, 'finishing' rids the surface of any roughness and imperfections, yet retains the character of the piece. The final buff is undertaken using a fine polishing cloth.